Design&Development --- Personalized customization

Since the establishment of the design and development department in 2009, we have introduced 4 outstanding talents with many years of design experience from famous company. After many years practical experiences, we have formed a very mature design and development team. We can customize the products that are specific to you according to your needs,all you need to do is provide us with 2D or 3D drawings, or your sample

![Dongguan Fuyao Precision Mould Co., Ltd. Dongguan Fuyao Precision Mould Co., Ltd.]()

![Dongguan Fuyao Precision Mould Co., Ltd. Dongguan Fuyao Precision Mould Co., Ltd.]()

MOuLDING MAKING ---Provide you with the perfect solution

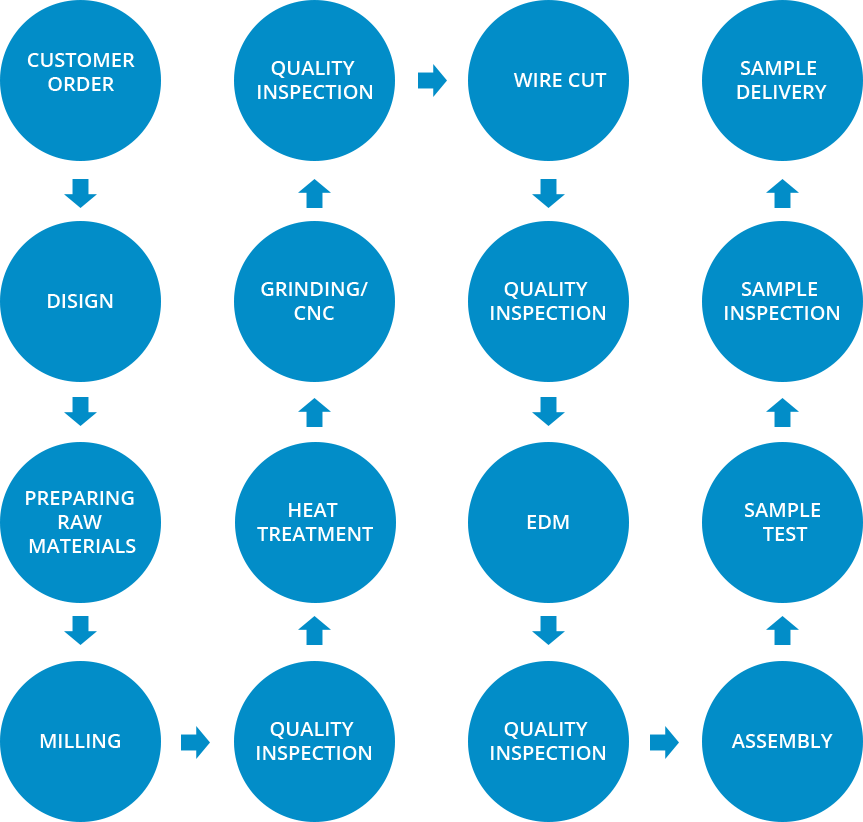

We have very advanced technology and mature experience in the manufacture of precision injection moulds and precision metal moulds. We have a strict operation specifications and management in the production flow and process , which can reduce the loss of materials and labor as mu ch as possible, to the greatest extent meet or exceed customer expectations, and strive for greater profit and better products for customers

Process and quality control flow chart

We commit to respond within 24 hours.

The lead time is very short and flexible.

We provide one-to-one service for each customer, eliminating all the complicated processes.

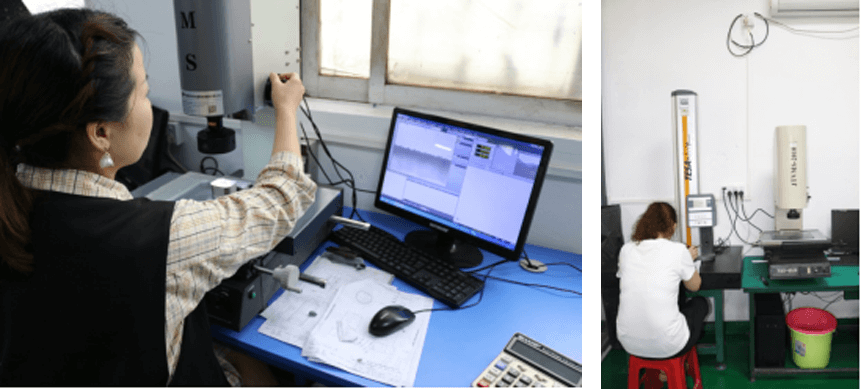

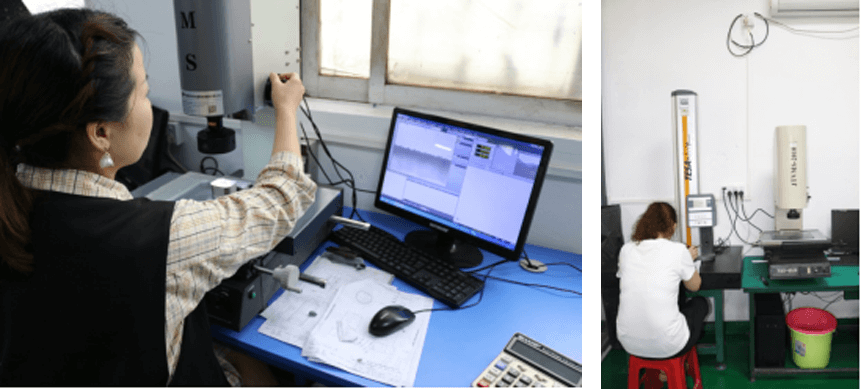

We have introduced high-precision Inspection equipment from Japan and experienced inspectors to ensure that our products meet international standards.

We carry out strict quality control on every process and strive to minimize tolerance values.

Processing Service ---24 hours for you

We have 14 years of experience in mould processing, specializing in a variety of complex, highly sophisticated mould parts processing services.

We have a variety of imported processing equipment to meet the various processing needs of our customers.

Major Equipment

QC

We have introduced high-precision Inspection equipment from Japan and experienced inspectors to ensure that our products meet international standards .

We carry out strict quality control on every process and strive to minimize tolerance values.

Incoming Material Inspection

All raw materials must be verified after they are delivered. We will strictly control the size and hardness of the raw materials to ensure the service life of the moulds and maximize the profitability of your operations.

Manufacturing inspection

Measurement of each mould part and electrode is essential during the manufacturing process. We set quality inspections in every process. The advantage of this is that we can find any possible errors in advance and avoid wasting time and money.

Finished products and shipment inspection

Finished parts are finally inspected by our Quality Assurance Manager prior to shipment and checked for packing to ensure that the goods arrive safely at our customers.

Certification

In order to provide customers with reliable quality assurance, we have passed the ISO9001:2015 quality management system certification to ensure that our products can meet internationally recognized industry standards, and we will continue to advance beyond the international standards.

“Click here to download the PDF certification ISO9001: 2015 "